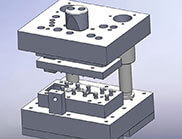

CAD/CAM Design

Regent's Engineering Department has the latest CAD/CAM software allowing us to quickly interface with customers, working with them as a team, assuring their components have the best design and most effective approach to manufacturing. We are able to produce 3D modelling, showing customers’ potential components and possible improvements where appropriate.

This process also enables graphic viewing of the finished item with different finishing processes. Using our 3D modelling capabilities means rapid and accurate quoting of competitive prices with production lead times for your component or assembly.

Toolmaking

We've made a big investment in tool manufacture and maintenance and it's paying dividends for both us and our customers.

Not only do our customers get the lowest possible cost of tooling but having been in the business for over 50 years we use this experience to cut out operations from the manufacturing process that enables us to offer the most competitive component prices.

Our Engineering Team love a project so however simple or complex your components are, Regent can be "Your Partners in Presswork Production".

Fabrications

We undertake welded fabrication of both pressed parts and those formed through other processes, which include machined components, box sections, tube, bar and flat bar as well as free issue material.

Our investment in 4 robotic welding cells enable us to offer highly competitive prices for this work together the accuracy and consistency that robots achieve.

Quality Control

We are an NQA certified ISO 9001:2015 company, with further quality accreditations from “Blue Chip” customers whilst simultaneously working towards the automotive standard TS 16949.

During 50 years of business, we have developed an excellent supply chain and all materials entering the company, being of certified standards.

Our fully integrated MRP II production management system allows manufacturing and quality, full batch traceability for every stage of the operation from material procurement through to finishing and shipping with options for release documentation where required.

In addition, our fully equipped quality department with UKAS certificated equipment assists our driving towards “zero defect” production.

Pressings

The plant operates 30 presses from 10 to 400 tonne, which offer the capacity for small (hand tool strip) medium (pick & place) through to full high volume production (multi stage coil fed) and working with a host of materials from steels including stainless plus brass, copper, phos bronze and aluminium.

Automated Coil Fed Production

We run high volume production through automated coil fed machines running multiple shifts when required to

achieve large batch production quickly.

Strip Fed Production

We use Strip fed production when this gives us the greatest level of efficiency for the volumes required.

Single Stage Pick & Place Presswork

Single stage secondary operations can be carried out by our machine operators for large components not

suited to progressive or auto lines or where immediate quality control and inspection is desirable.

Deep Drawing

We manufacture deep drawing of ferrous and non-ferrous materials up to a depth of 100mm.

Fibre optic Laser Cutting

Regent Engineers has the latest technology when it comes to laser cutting. We have the capability to cut mild steel up to a thickness of 25mm and the ability to cut a range of other materials. Our laser has an automatic sheet loading system that enables us to run ‘lights out’ production giving quality parts with fast turn round at competitive prices.

CNC Machining & Turning

Recent major investment has seen the growth of our CNC lathe and machining centre department. Complementing our existing capacity has been the recent introduction of both a new 4 axis CNC lathe and CNC bar feed lathe adding to our ability to produce both volume and prototype precision parts, whilst maintaining an efficient cost effective response.

Component Finishing

Regent Engineers offer a complete one stop shop product service from design through to component finishing. Finishes we offer include barrelling- de-greasing and de-burring, powder and vinyl coating and electro-plating.

Thread Rolling

Regent now produces threaded bar and is capable of manufacturing it in all the unified forms for example metric, trapezoidal and knurled Whether you need fully threaded or double ended studs, specialty fasteners, lead screws, or knurled parts we have the capabilities to get the job done right.